Solutions

Artificial Sand and Aggregate Production Line

Artificial Sand and Aggregate Production Line

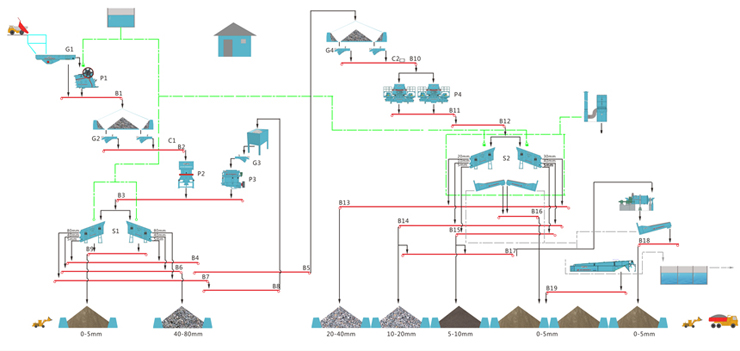

This production line is widely used in water conservancy and hydropower, road, bridge and railway construction. GAOKE &Dahua can provide comprehensive aggregates production line solutions and projects general contracting scheme with an annual output of 30,000 - 8,000,000 tons.

Production Capacity: 60-1000t/h

Application Fields: water conservancy and hydro-power, road, bridge and railway construction

Production Line The Major Equipment of Artificial Sand and Aggregate Production Line:

The Major Equipment of Artificial Sand and Aggregate Production Line:

Construction Waste Recycling Production Line is mainly composed of jaw crusher, impact crusher, cone crusher, sand making machine, vibrating feeder and so on.

The Advantages of Artificial Sand and Aggregate Production Line

Eco-Friendly: To protect the environment is to safeguard the production capacity

Safety: Invest in safety is to maximize your welfare

Economical: Perfect design, low investment and operation cost, all for the benefit of our customers.

Quality: Good shape granularity, feasible granularity arranges to meet customer needs.

Smart: Automatic control, Real-time monitor to improve the working efficiency.

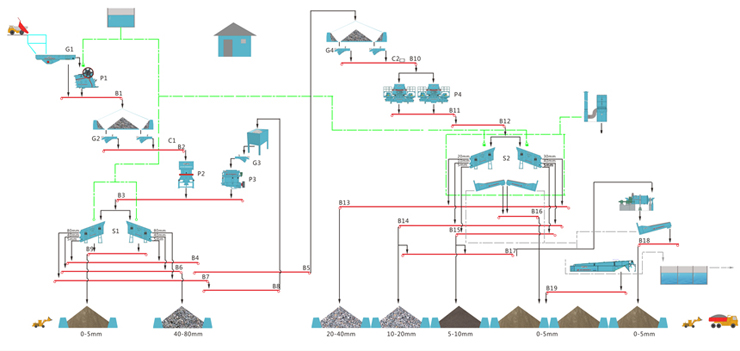

This production line is widely used in water conservancy and hydropower, road, bridge and railway construction. GAOKE &Dahua can provide comprehensive aggregates production line solutions and projects general contracting scheme with an annual output of 30,000 - 8,000,000 tons.

Production Capacity: 60-1000t/h

Application Fields: water conservancy and hydro-power, road, bridge and railway construction

Production Line

Construction Waste Recycling Production Line is mainly composed of jaw crusher, impact crusher, cone crusher, sand making machine, vibrating feeder and so on.

The Advantages of Artificial Sand and Aggregate Production Line

Eco-Friendly: To protect the environment is to safeguard the production capacity

Safety: Invest in safety is to maximize your welfare

Economical: Perfect design, low investment and operation cost, all for the benefit of our customers.

Quality: Good shape granularity, feasible granularity arranges to meet customer needs.

Smart: Automatic control, Real-time monitor to improve the working efficiency.